Disruptive Procurement challenges status quo, drives value and innovation.

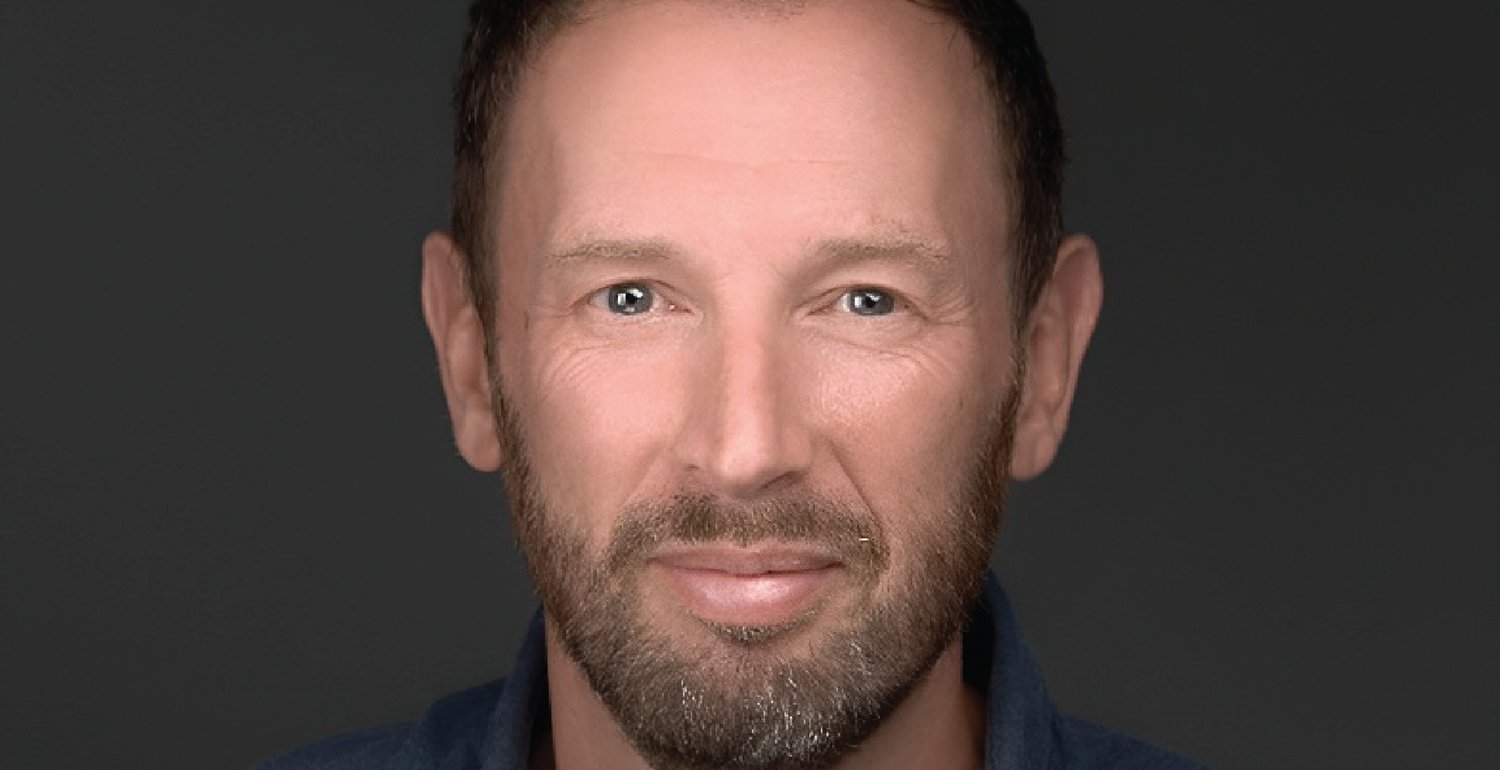

DPW sat down with Kearney’s Michael Strohmer to discuss his recently published book “Disruptive Procurement – Winning in a Digital World” and how he sees the future of procurement.

In your book, you describe the end of procurement as we know it. What leads you to assert that procurement itself will suffer disruption?

Strohmer: We have seen seismic redefinitions of the economic environment that include the changing geopolitical balance, core shifts in economics, the impact of exponential technologies, eroding institutions and the decay of public trust. And just recently we have experienced, and are still experiencing, the implications of a pandemic that is unprecedented. When we wrote the book, we could not have foreseen a phenomenon like the coronavirus pandemic, but we did know that we are living in a time of deep uncertainty and ongoing change. We have analyzed a varied collection of what are called “ending eras”. Each of them is in itself highly significant. Taken together, they announce a fundamental shift in our way of doing business, in shaping our supply chains and, as a consequence, in the procurement function. At the same time, they signal the need for a more innovative approach to procurement, sourcing strategies, management of global supply chains, and interlinked international operations. And this is where the new technologies that drive this disruption itself will help us.

Let’s look at the technological shift. What developments are rendering our current procurement module obsolete?

Strohmer: Kearney has worked closely with the World Economic Forum on its “Shaping the Future of Production” initiative, which analyzes to what extent production-relevant technologies will transform the very nature of production through 2030. The point of departure for the analysis is that in the fourth industrial revolution, five “exponential” technologies can and likely will alter the production landscape for ever:

-

Artificial intelligence (AI):

At the core of the ongoing remarkable advances in AI is the continued breathtaking progress being made in computing speeds and capacities. This implies a faster rate of evolution from “narrow” AI, in which machines outperform humans in narrow functions, to “general” AI, in which machines are able to successfully integrate multiple functional areas. All the while, they will be en route to “super AI”—machine learning at a level where machines can teach themselves and outperform humans on virtually every level.

-

Internet of Things (IoT):

The IoT is also growing rapidly. Soon more devices around us will be connected than are not. For business, the advances in the IoT will serve as the foundation for sweeping digital transformations in which they will optimize existing operating models as well as innovate for the future.

-

Additive manufacturing/3D printing:

The menu of materials that can be printed – which until recently was restricted mainly to plastics and resins – now includes metals and even biomaterial. This has huge implications for procurement: In the future, will companies buy in their products or will they print them?

-

Augmented reality (AR):

The integration of business training and operational functions associated with artificial reality and virtual reality (VR) is also growing rapidly.

-

Advanced robotics:

The global balance of power in the use of industrial robots has shifted rapidly from Western countries to Asia and is forever changing the business model underpinning global value chains.

Taken together, these five technological trends make today’s procurement system look outdated. Buyers sitting at their desks editing Excel lists can no longer keep pace with these new capabilities. The procurement specialists of today will no longer exist tomorrow. Their responsibilities can be carried out smarter, more efficiently and more effectively when automated. It is not without reason that a CEO once asked us whether in the future procurement will have its own app.

Does that mean that procurement experts will at some point find themselves out of work because robots have taken over their job?

Strohmer: Yes and no! To be sure, many operational activities will no longer have to be carried out by experts, but will be performed by AI systems – which will also do a better job of it, too. BUT: Procurement will become more strategic, innovative and value-adding. At present, procurement is still seen as a cost pool that is responsible for 50 to 70 percent of the costs of manufacturing companies. If, on the other hand, we take a look at its contribution to value creation, a completely new profile of procurement emerges. Procurement departments are expected to do more than just squeeze suppliers’ margin down to the very last penny – they drive corporate success and know how to skillfully utilize the innovative capacity of their suppliers. Procurement has the potential to act as a disruptor. Digitalization is fundamentally changing the way procurement is handled in companies and how its disruptive forces can take effect. But for this to happen, procurement too must change – to become smarter, speedier and smaller. Its knowledge of suppliers and where their potential value added may lie is vital if businesses are to be competitive. Numerous approaches such as the supplier fitness program or 360° supplier development can help in this respect. Furthermore, buyers must know how value added can be created for their own company: What’s important to customers when it comes to service? How must specifications be modified so that delivery times and costs can be optimized in the customers’ interest? All these are questions that are not a million miles away from what’s on the mind of board members. Procurement should not be positioned three levels below the CFO, but should report directly to the management board.

Michael Strohmer is Partner & Managing Director EMEA and Co-Head Operations Practice at Kearney. He is also the author of the book “Disruptive Procurement – Winning in a Digital World” is which is now available on Amazon.